Aseptic Bag Filling Machine

Aseptic Bag Filling Machine: Precision & Reliability for Sterile Liquid Packaging

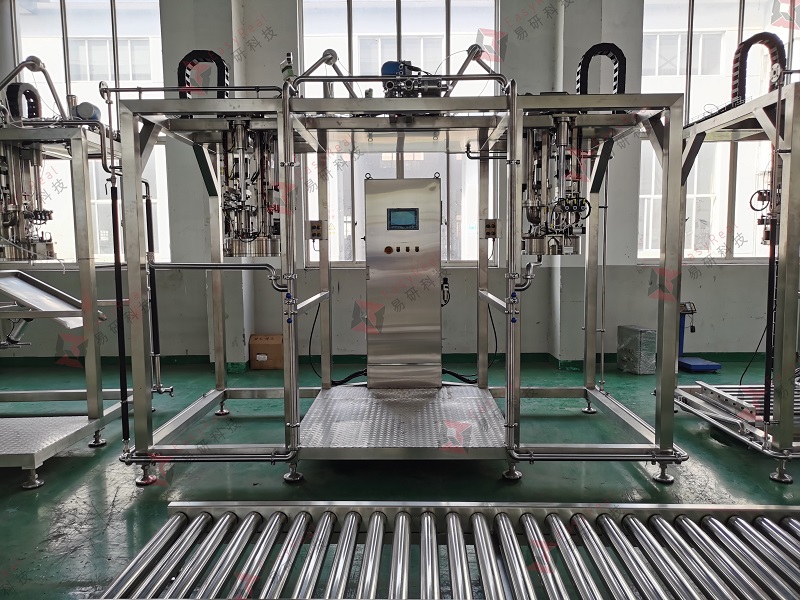

The Aseptic Bag Filling Machine by EasyReal is engineered to fill sterile liquid food products (e.g., fruit juices, tomato paste, purees, jams, cream) into 200L or 220L aseptic bags within drums/1~1400L within bulk boxs. Designed for high-quality demands, this robust machine ensures product integrity and extended shelf life, making it ideal for sensitive liquid food materials requiring stringent hygiene standards.

Key Benefits:

- Extended Preservation: Integrates seamlessly with UHT sterilizers to form a complete aseptic filling line. Post-processing, natural juices/purees retain freshness for 12+ months at ambient temperatures, while concentrated products (e.g., pastes) last 24+ months.

- Precision & Versatility: Handles diverse viscosities and product types with ±0.5% filling accuracy.

- User-Friendly Operation: Simplified touchscreen controls streamline bag selection, sterilization, filling, and sealing.

Core Components:

- Aseptic filling head

- Precision control system

- Steam sterilization unit

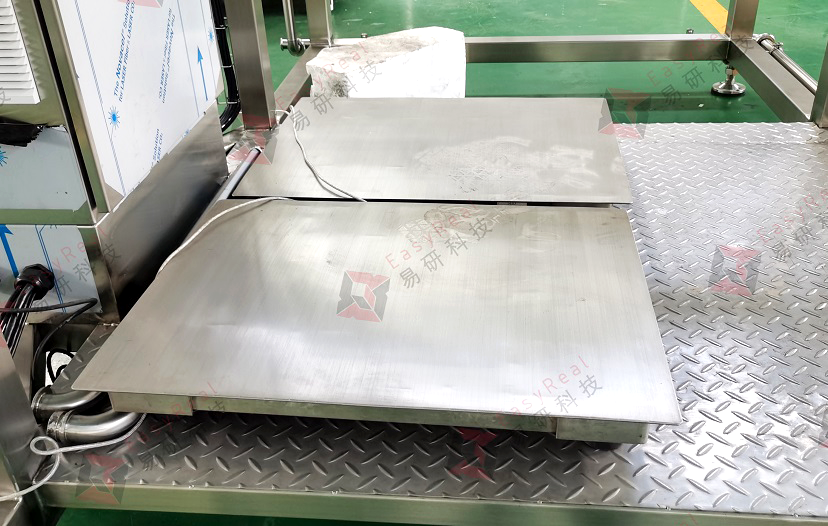

- Pneumatic tray (1–25L bags)

- Customizable conveyors (roller/belt)

- Durable stainless-steel frame

How It Works:

- Select Bag Type: Choose parameters via intuitive touchscreen.

- Sterilize & Prep: Automated steam injection ensures a sterile environment.

- Fill & Seal: Precise volumetric filling and hermetic sealing in a contamination-free chamber.

- Output: Finished bags are conveyed for storage or transport.

Applications:

Ideal for semi-finished liquid products destined for food factories or export, including:

- Tomato paste & vegetable concentrates

- Fruit pulps, purees, and dairy products

- High-acid or viscous liquids (e.g., jams, syrups)

Why EasyReal?

Our Aseptic Bag Filling Machine combines cutting-edge automation with industrial durability, reducing downtime and ensuring compliance with global food safety standards. Trusted by manufacturers worldwide, it’s the go-to solution for sterile, large-volume packaging.

Expert Engineering, Tailored Solutions for Every Production Need

At EasyReal TECH, our experienced engineering team specializes in designing adaptable aseptic packaging systems to meet diverse industrial demands. Whether your facility requires high-speed automation or compact configurations, we deliver precision-engineered solutions that align with your unique production environment.

Customizable Aseptic Filling Systems:

- Bag-in-Box & Bag-in-Bin Machines: Ideal for flexible packaging of sterile liquids in varied container formats.

- Aseptic Bag in Drum Filling Systems: Configured to your exact specifications, including:

- Single/Double/Multi-Head Fillers: Scale throughput efficiently with modular designs.

- Compact to High-Capacity Models: Choose from Single-Drum Fillers or space-efficient 4-Drum Tray Systems for bulk operations.

Why Partner with EasyReal?

- Precision Adaptability: Modify machine parameters (speed, volume, sterilization protocols) to match your product’s viscosity and sterility requirements.

- Future-Ready Design: Upgrade or expand systems seamlessly as production needs evolve.

- Global Complian

1.Robust Construction

Premium SUS304 stainless steel main structure ensures corrosion resistance and compliance with food-grade hygiene standards.

2.European Engineering Excellence

Combines Italian processing technology with German automation systems, fully compliant with Euro Standard EN 1672-2.

3.Multi-Scale Compatibility

Spout sizes: 1"/2" (25mm/50mm) standard options

Bag capacity: 200L-220L standard models (Customizable from 1L to 1400L)

4.Smart Control System

Independent Siemens S7-1200 PLC with HMI touchscreen enables precise parameter control and real-time monitoring.

5.Sterilization Assurance

Full SIP/CIP integration (pH-resistant surfaces)

Steam barrier protection for filler head (120°C sustained)

Triple-sealed moving components

6.Dual Precision Measurement

Option for:

✓ Coriolis mass flowmeter (±0.3% accuracy)

✓ Dynamic weighing system (±5g resolution)

7.Maintenance-Optimized Design

Tool-free quick-change parts

<30 min CIP cycle time

Universal connector interfaces

8.Global Component Strategy

Critical systems feature:

• Festo/Burkert pneumatics

• SICK sensors

• Nord gearmotors

• IFM monitoring modules

9.Energy Efficiency

≤0.15kW·h/L power consumption with heat recovery system

10.Certification Ready

Pre-configured for CE/PED/3-A certification documentation

1. Juice & Concentrates

Full-spectrum processing for NFC juices (Not From Concentrate) and 65°Brix+ concentrates.

2. Puree Solutions

Homogenized fruit/vegetable purees with ≤2% pulp sedimentation, compatible with 8°-32°Brix ranges.

3. Paste & Jam Systems

High-shear processing for particle sizes ≤2mm, suitable for 40°-85°Brix viscosity products.

4. Coconut Water Series

Aseptic filling for clear coconut water (pH 5.0-6.5) and 3:1 concentrate variants.

5. Coconut Derivatives

Stable emulsification for:

✓ Coconut milk (18-24% fat content)

✓ Coconut cream (25-35% fat content)

6. Acidic Liquid Specialization

- Low-acid (pH ≥4.6): Dairy alternatives, plant proteins

- High-acid (pH ≤4.6): RTD teas, fermented beverages

7. Syrup Applications

Precision dosing for:

✓ Simple syrups (1:1 ratio)

✓ Flavored syrups (0.5-2.0% flavor load)

8. Soup & Broth Lines

Multi-phase blending for:

◆ Cream soups (≤12% fat)

◆ Clear consommes (≤0.5% turbidity)

◆ Particulate soups (≤15mm chunks)

|

Name |

Single head Aseptic Bag in Drum Filling System |

Double head Aseptic Bag in Drum Filling System |

Bag in box Single head Aseptic Filler |

Bag in box Double head Aseptic Filler |

BIB & BID Single head Aseptic bag Filling Machine |

BIB & BID Double head aseptic bag Filling Machine |

BID & BIC Single head Aseptic liquid Filling Machine |

BID & BIC Double head Aseptic liquid Filling Machine |

|

Model |

AF1S |

AF1D |

AF2S |

AF2D |

AF3S |

AF3D |

AF4S |

AF4D |

|

Bag Type |

BID |

BIB |

BIB & BID |

BID & BIC |

||||

|

Capacity |

up to 6 |

up to 12 |

up to 3 |

up to 5 |

up to 12 |

up to 12 |

up to 12 |

up to 12 |

|

Power |

1 |

2 |

1 |

2 |

4.5 |

9 |

4.5 |

9 |

|

Steam Consumption |

0.6-0.8 Mpa≈50(Single head)/≈100(Double head) |

|||||||

|

Air Consumption |

0.6-0.8 Mpa≈0.04(Single head)/≈0.06(Double head) |

|||||||

|

Bag Size |

200, 220 |

1 to 25 |

1 to 220 |

200, 220, 1000, 1400 |

||||

|

Bag Mouth Size |

1" & 2" |

|||||||

|

Metering Method |

Weighing System or Flow Meter |

Flow Meter |

Weighing System or Flow Meter |

|||||

|

Dimension |

1700*2000*2800 |

3300*2200*2800 |

1700*1200*2800 |

1700*1700*2800 |

1700*2000*2800 |

3300*2200*2800 |

2500*2700*3500 |

4400*2700*3500 |

1. Food Safety Compliance

✓ All food-contact surfaces: FDA/EC1935-certified SUS304 stainless steel

✓ Non-contact framework: IP65-rated powder-coated steel

✓ Seal materials: FDA 21 CFR 177.2600 compliant EPDM/Silicone

2. Value Engineering Solutions

◆ TCO(Total Cost of Ownership)optimized designs

◆ ≤15% energy saving vs. industry benchmarks

◆ Modular architecture for ≤30% expansion cost

3. Technical Partnership Program

- Phase 1: 3D process simulation & DFM(Design for Manufacturing)analysis

- Phase 2: CE/PED/3-A compliant mechanical drawings (AutoCAD/SolidWorks)

- Phase 3: FAT documentation package (IQ/OQ/PQ protocols)

4. 360° Support Ecosystem

✓ Pre-sales: Raw material analysis lab services

✓ Implementation: CIP/SOP workflow optimization

✓ Post-sales: Predictive maintenance algorithms

5. Turnkey Implementation

◆ 14-day installation timeline (from EXW to commissioning)

◆ Bilingual training modules:

- Operational: GMP/HACCP compliance

- Technical: PLC programming basics

- Maintenance: Spare parts management

6. Service Commitment

✓ 12-month comprehensive warranty (incl. wear parts)

✓ ≤4hr remote response / ≤72hrs onsite support

✓ Lifetime software upgrades (v2.0→v5.0 compatibility)

✓ ≤3% downtime guarantee with AMC plans

EasyReal Tech. is a leading manufacturer of fruit and vegetable processing line equipment, offering tailored turnkey solutions from A to Z, designed to meet each client's specific needs. Among our core products, the Aseptic Bag-in-Drum Filling System stands out as the most popular. This machine has earned multiple patents and is widely praised by customers for its safety and reliability.

To date, EasyReal has achieved ISO9001 quality certification, European CE certification, and the prestigious State-certified High-tech Enterprise honor. Through long-term collaborations with internationally renowned brands such as Germany's STEPHAN, Germany's RONO, and Italy's GEA, we have developed over 40 pieces of equipment with independent intellectual property rights. Our products have been trusted by major corporations including Yili Group, Ting Hsin Group, Uni-President Enterprise, New Hope Group, Pepsi, Myday Dairy, and more.

As EasyReal continues to evolve, we now offer comprehensive one-stop services that cover everything from project consultation and process development to solution design, construction, and after-sales support. We provide customized services tailored to the unique needs of each client, striving to deliver projects that exceed expectations.