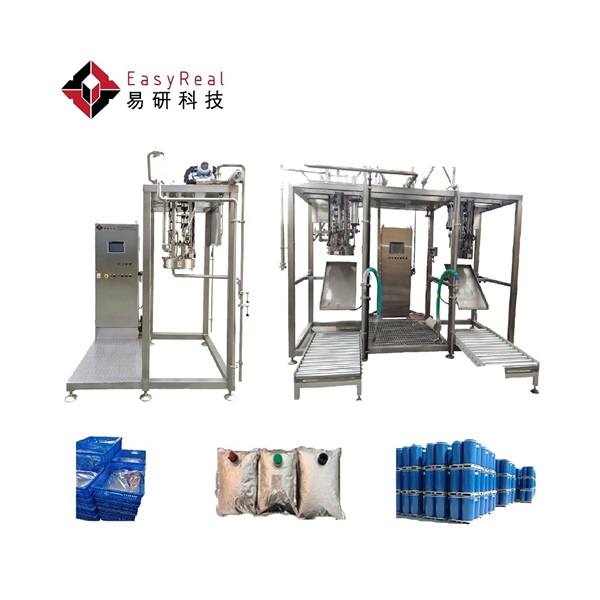

Flexible Aseptic Bag Filling Machine for 1 to 1400 Liters Aseptic Bags

ER-AF Series Flexible Aseptic Filling Machine is designed to provide the highest possible level of sterility and productivity for filling bulk aseptic bag-in-box, bag-in-drum and ton-in-bin containers.

- Importance of Flexible Bag Aseptic Filling System

For years on the market, ER-AF Series Aseptic Filling Machine is constantly evolving to offer the maximum functionality and ease of use. With the application of additional devices, ER-AF Series Flexible Bag-in-box Filling Equipment - Aseptic Bag in Drum Filling Machine - IBC Filling Equipment Format can fill 1-3-5-10-20-25-200-220-1000-1400 liter bags in same plant.

The ER-AF Series Flexible Aseptic Filling Machine is now proven worldwide as the gold standard for aseptic bag filling which virtually eliminates the possibility of filling contamination and spoilage.

- Multifunction application for flexible aseptic bag filler

ER-AF Series Flexible Aseptic Bag Filling Machine can fill a wide range of products, such as fruit and vegetable puree, juice, jam and concentrates, and dairy products, dices, pulp, soups and low acid products.

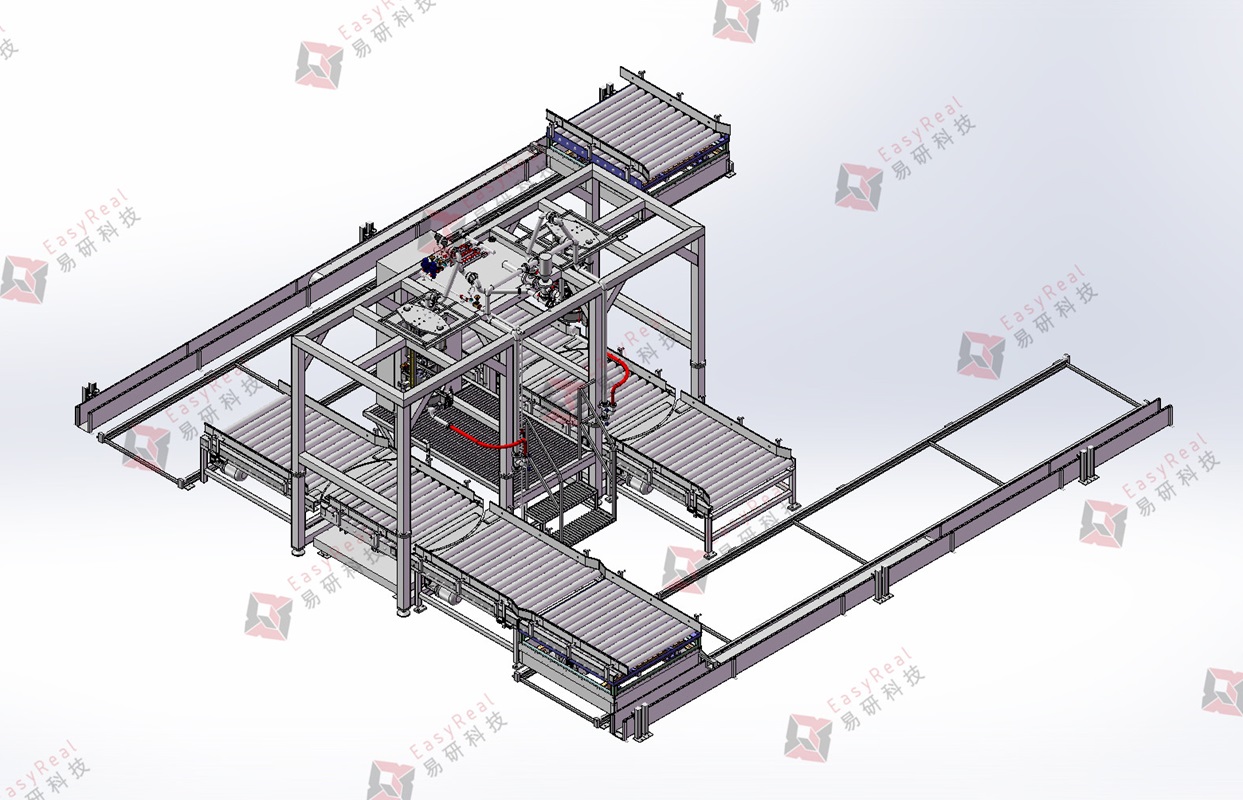

If drums with 200-liter or/and 220-liter bags are used, these are fed by means of a pallet in a 4 unit arrangement. Thanks to the 360° rotating roller conveyor, the filling is completed without unloading the drums from the pallet. The same roller conveyor can also feed bins containing 1.000-liter or 1400-liter bags.

Moreover, as for the pre-sterilized bags, they are normally made of aluminum foil-plastic which can effectively block sunlight ans oxygen, and extend the product’s shelf life maximum."

1. High Reliability.

2. Much Flexible Depend on Actual needs with Different Bags.

3. Complete Process Guarantee.

4. Modular Aseptic Filling Machine

5. Easy Operation.

6. High Accurate.

7. Full Sanitary and Aseptic Design.

8. Wide Range of Applications.

9. Much Low in Maintenance costs.

1. Fruit and vegetable Juice.

2. Fruit and Vegetable Puree.

3. Fruit and Vegetable Concentrate.

4. Liquid Product with Pieces.

5. Products with High Acid.

6. Products with Low Acid.

7. Health and Nutritional Products.

|

Name |

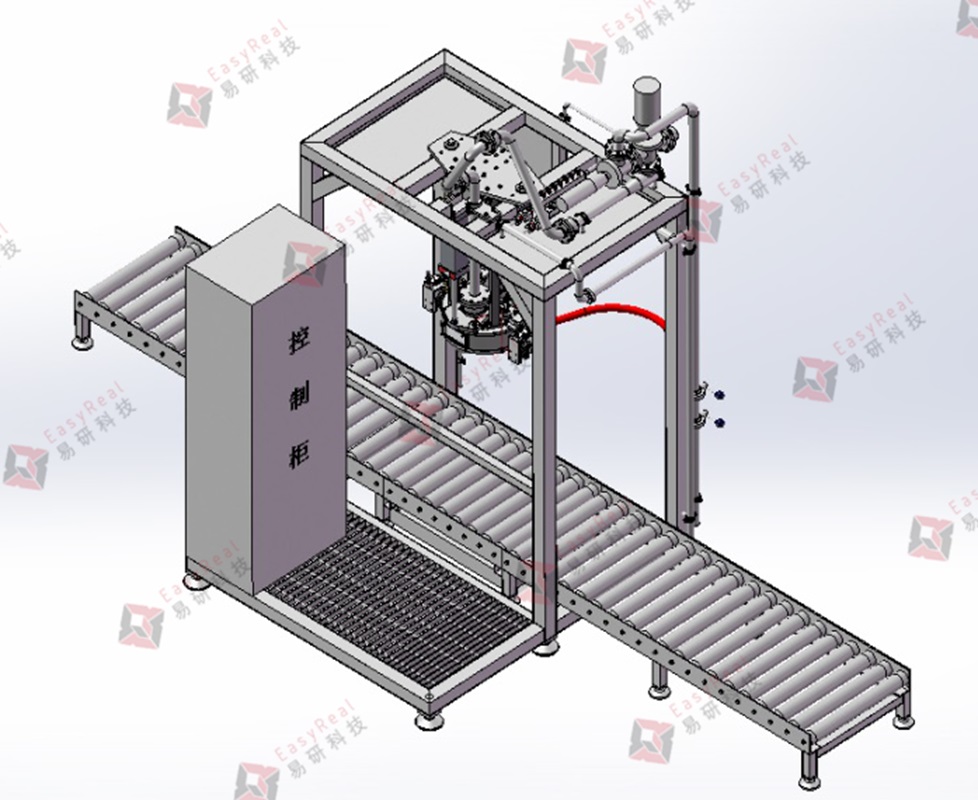

Single head Aseptic Bag in Drum Filling Machine |

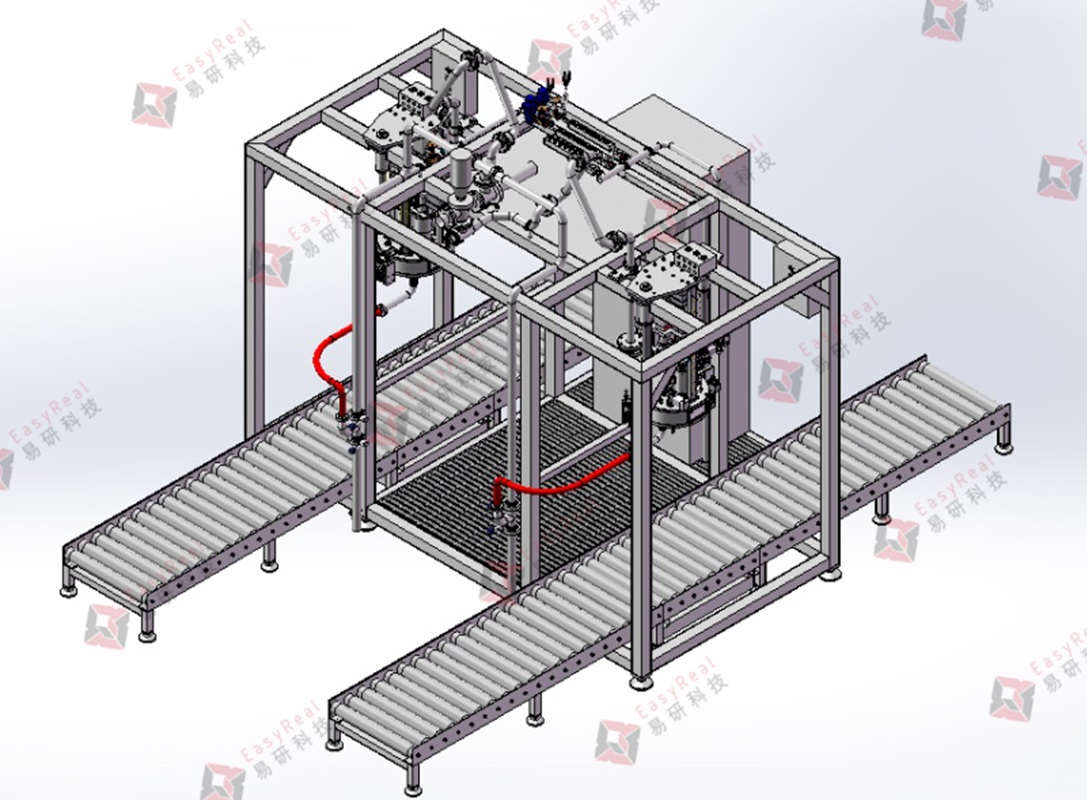

Double head Aseptic Bag in Drum Filling Machine |

Single head Aseptic Bag in Box Filler |

Double head Aseptic Bag in Box Filler |

Flexible Single head Aseptic Bag in Box Filler & Aseptic Bag in Drum Filling Machine |

Flexible Single head Aseptic Bag in Box Filler & Aseptic Bag in Drum Filling Machine |

Flexible Single head Aseptic Bag in Drum Filling Machine & IBC Filling Equipment (4-drum in 1-tray & bag-in-bin) |

Flexible Double head Aseptic Bag in Drum Filling Machine & IBC Filling Equipment (4-drum in 1-tray & bag-in-bin) |

|

Model |

AF1S |

AF1D |

AF2S |

AF2D |

AF3S |

AF3D |

AF4S |

AF4D |

|

Capacity |

up to 6 |

up to 12 |

up to 3 |

up to 5 |

up to 12 |

up to 12 |

up to 12 |

up to 12 |

|

Power |

1 |

2 |

1 |

2 |

4.5 |

9 |

4.5 |

9 |

|

Steam Consumption |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

|

Air Consumption |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

0.6-0.8 Mpa |

|

Bag Size |

200, 220 |

200, 220 |

1 to 30 |

1 to 30 |

1 to 220 |

1 to 220 |

200, 220, 1000, 1400 |

200, 220, 1000, 1400 |

|

Bag Mouth Size |

1" & 2" |

|||||||

|

Metering Method |

Loading Cells or Flow Meter |

Flow Meter |

Loading Cells or Flow Meter |

|||||

|

Dimension |

1700*2000*2800 |

3300*2200*2800 |

1700*1200*2800 |

1700*1700*2800 |

1700*2000*2800 |

3300*2200*2800 |

2500*2700*3500 |

4400*2700*3500 |

1. Aseptic Head(s)

2. Siemens Control System

3. Measuring System( flowmeter or loading cells).

1. Aseptic Bag in drum Filling Machine- 220/220 liters Format.

2. Aseptic Bag-in-box Filling Equipment- 1 to 30 liters Format.

3. Flexible Aseptic Bag-in-box Filling Equipment - Aseptic Bag in Drum Filling Machine- 1 to 220 liters Format.

4. Aseptic Bag IBC Filling Equipment- 1000 to 1400 liters Format.

5. Flexible Bag-in-box Filling Equipment - Aseptic Bag in Drum Filling Machine - IBC Filling Equipment- 1 to 1400 liters Format.

6. Flexible Aseptic Bag in Drum Filling Machine - IBC Filling Equipment Format- 200 to 1400 liters Format.

Shanghai EsayReal with over 20-year experience, combined with the most advanced science and technology, EasyReal is considered as the professional manufacturer for supplying ER-AF Series Aseptic Filling Machine for filling different liquid products, like puree, juice, concentrate, etc. Depend on actual needs, EasyReal Tech could supply suitable solutions to meet actual needs which is easy to use with high quality and reliability.

Warmly welcome global friends come for visit and inspect EasyReal’s Shanghai Factory which is located in Shanghai city, China.