Hot-selling High-quality Carrot Processing Line

The carrot processing line is combining Italian technology and conforming to Euro-standard. Due to our continuous development and integration with international companies like STEPHAN Germany, OMVE Netherlands, Rossi & Catelli Italy, etc, Easyreal Tech. has formed its unique and beneficial characters in design and process technology. Thanks to our much experience over 100 whole lines, Easyreal TECH. can offer production lines with capacity from several hunderd KG to 10 tons per hour and customizations including plant construction, equipment manufacturing, installation, commissioning and production.

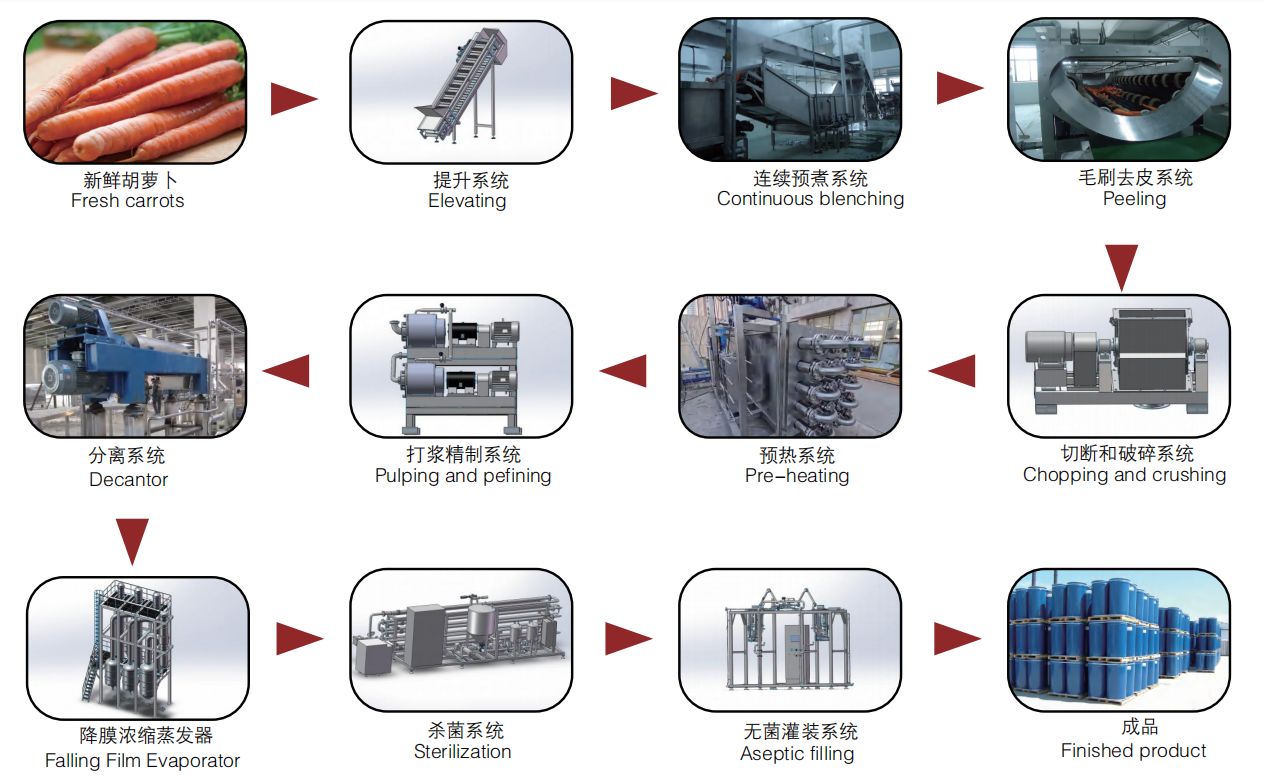

Complete line for carrot processing, to obtain carrot juice, carrot pulp, puree, carrot paste, juice concentrate, carrot juice beverage. We design, manufacture and supply complete processing line including:

---Washing and sorting line with water filtering system

–-Continuous blenching machine. It is fully automatic. The design concept is advanced, high degree of automation. The structure is all made of high quality stainless steel. And it fully meet the health requirements of food processing.

---Brush Peeling and Chopping. The Brush peeler is specially design to peel carrot. Peeled carrots are chopped before going to the treatment line. The chopping dimensions depend on the required extraction (pulp or pressed juice). The chopped carrots are heated in a tubular cooker to soften the fibers and to get consequently the maximum juice yield.

---Belt press. For making juice, the press is ideal for choice.

---Pulping and refining machine. For making pulp or paste, this machine is necessary.

–-Continuous evaporators, simple effect or multi effect, completely controlled by PLC. Worth mentioning, falling film typy and forced circulation type for choice.

– Aseptic filling machine complete with Tube in Tube Aseptic Sterilizer specifically designed for high viscous products and Aseptic Filling Heads for aseptic bags of various sizes, completely controlled by PLC.

The juice/ pulp/ concentrate in aseptic drum can be further processed to beverage, baby food in tin can, bottle, pouch, etc.Or directly produce end product from fresh carrot.

Easyreal TECH. can offer complete production lines with capacity from several hunderd KG to 10 tons per hour and customizations including plant construction, equipment manufacturing, installation, commissioning and production. The design concept of this production line adopts advanced design idea. It has high degree of automation; Main equipments are all made of high quality food grade stainless steel, accords with the hygienic requirements.

Several products can be produce from using carrot processing line:

1. Carrot pulp/puree

2. carrot concentrater paste

3. Carrot juice (clear juice/ cloudy juice)

4. Juice concentrate

5. Fermented carrot products

6. Carrot beverage

1. Main structure is SUS 304 and SUS316L stainless steel.

2. Combined Italian technology and conform to Euro-standard.

3. Special design for saving energy (energy recovery) to increase the energy utilization and greatly reduce production cost.

4. Semi-automatic and fully automatic system available for choice.

5. The end product quality is excellent.

6. High productivity, flexible production, the line can be customized depend on actual need from customers.

7. Low-temperature vacuum evaporation greatly reduces the flavor substances and nutrient losses.

8. Fully automatic PLC control fro choice to reduce the labor intensity and improve production efficiency.

9. Independent Siemens or Omron control system to monitor each processing stage. Separate control panel, PLC and human machine interface.

1. Realization of automatic control of material delivery and signal conversion.

2. High degree of automation, minimize the number of operators on the production line.

3. All electrical components are international first-class top brands, to ensure the stability and reliability of equipment operation;

4. In the process of production, man-machine interface operation is adopted. The operation and state of the equipment are completed and displayed on the touch screen.

5. The equipment adopts linkage control to automatically and intelligently respond to possible emergencies.