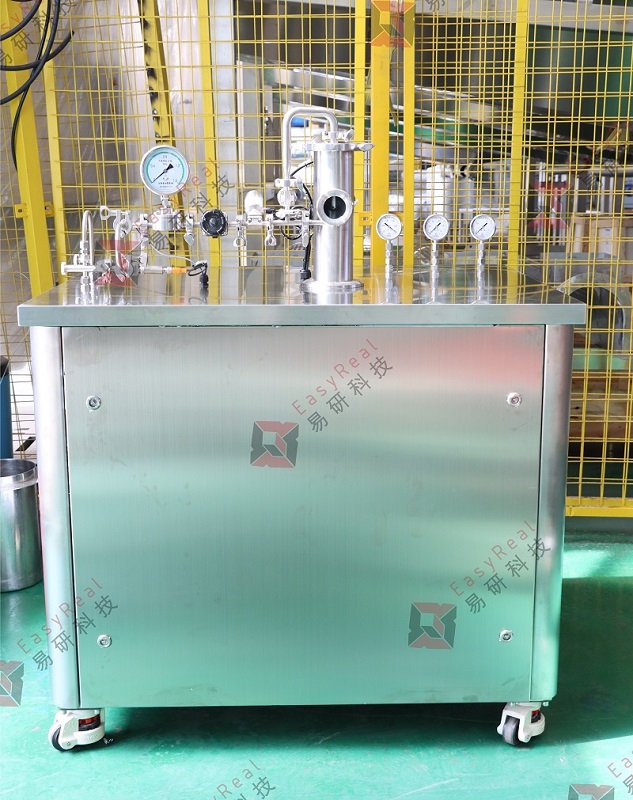

Lab HTST/UHT Mini Processor

What is the Lab UHT Processing Plant?

One of the core of EasyReal's product range is the Lab UHT Process Plant, a sophisticated solution designed to enhance the sterilization of liquid food through ultra-high temperature treatment. This advanced technology extends the shelf life of liquid food products while preserving their essential nutritional properties and taste profiles. Widely adopted in the food industry, this technology is esteemed for its ability to effectively deactivate a range of microorganisms, ensuring the safety and integrity of the final food product. The Lab UHT processors from EasyReal Tech are also recognized for their reliability, user-friendly interface, robust construction, ease of operation, and low maintenance requirements, making them a valuable asset for food production facilities.

How about Shanghai EasyReal's Lab UHT Processing Plant?

Shanghai EasyReal‘s Lab HTST/UHT Mini Processor Plant is equipped with precise temperature control and accurate flow rates, leading to reliable and repeatable processing conditions. With its user-friendly interface and flexibility to handle a range of viscosities and particulate sizes, the Lab HTST/UHT Processor is a valuable tool for product development, quality control, and research in the food and beverage industry. this processor offers a cost-effective solution for simulating industrial-scale production processes on a smaller scale.

Notably, the LAB UHT/HTST Processer and the Lab HTST/UHT Pilot Plant from EasyReal provide adaptable solutions to meet various processing needs within the food and beverage sector. Whether optimizing formulations, conducting shelf-life studies, or evaluating product characteristics, these processors offer a dependable platform for researchers and developers to explore and refine their creations. Trusted by educational institutions, research laboratories, and pilot plants, EasyReal's Lab UHT processors consistently deliver precise and reproducible processing conditions, fostering a culture of innovation and stringent quality control.

EasyReal Tech is a gold medal manufacturer specializing in the development and manufacture of laboratory ultra-high temperature processors, located in beautiful Shanghai, China. Our company attaches great importance to cutting-edge innovation and has various qualification certifications such as ISO9001, CE and SGS, which has laid the foundation for quality and continued development of professionalism and services. In addition, EasyReal Tech has obtained more than 40 independent intellectual property rights. Laboratory ultra-high temperature processors are tailored to the unique needs of R&D facilities, enabling scientists and engineers to advance crystallization technology and conduct groundbreaking research in their fields.

Raw Material → LAB UHT/HTST PROCESSOR Feed hopper → Screw pump → Preheating Section → Upstream Homogenization → Sterilizing and Holding Section (85~150℃) →(Downstream Aseptic Homogenization, Optional) →Water Cooling Section→(Ice Water Cooling Section, Optional) →Aseptic Filling Cabinet.

1. Easy to operate, Modular Design

2. Independent German Siemens/Japan Omron control system.

3. Mini input quantity 3~5L

4. Inline CIP and SIP function.

5. Data collection easily.

6. With high accurate temperature control.

7. Good reproducibility.

8. Low labor, high automation control.

9. Lab UHT processors, Upstream/Downstream Aseptic Homogenizer, DSI module and Aseptic filling cabinet can be integrated.

1. Fruit and Vegetable Juices

2. Fruit and Vegetable Puree

3. Dairy Products

4. Coffee & Tea Drinks

5. Seasonings

6. Additives

7. Soups & Sauce

8. Plant-based Milk

Experiment with just 3L!

Lab UHT Process Plant, equipped with the latest technology, empowers researchers to conduct trials with minimal product volume, significantly reducing ingredient requirements, preparation, start-up, and processing time. In addition, its capability to facilitate multiple trials in a day enhances R&D productivity. With convenient access to heat exchangers, the Lab UHT Process Plant allows for swift modification of process configurations.

All manual controls are strategically positioned at the front of LAB UHT/HTST PROCESSOR for easy operation. Siemens touch screen, boasting high resolution, provides a comprehensive real-time overview of the process dynamics including temperature, flow, and pressure. Furthermore, the PLC guides operators through startup, processing, cleaning, and sterilization procedures, streamlining operations and ensuring precision."