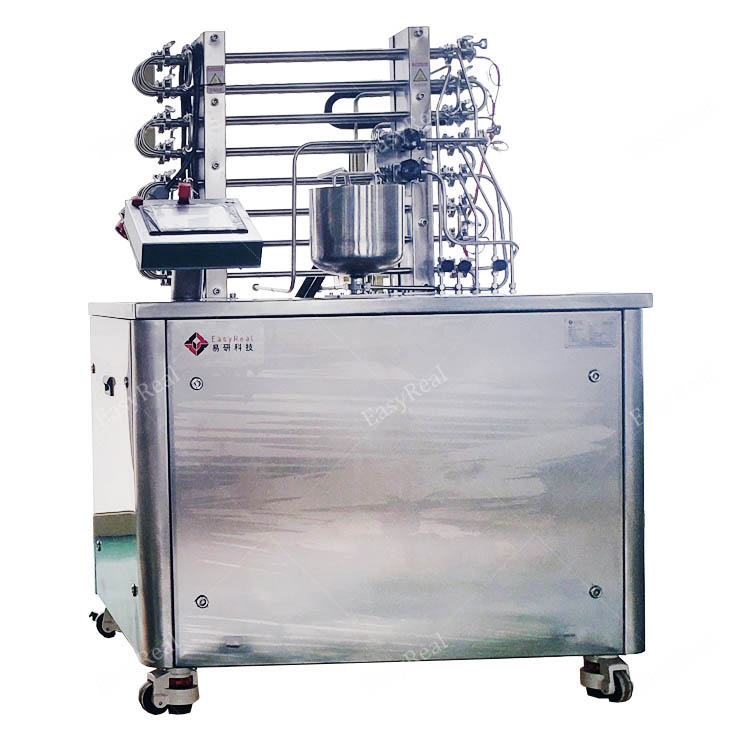

Lab UHT Sterilizer Pilot Plant

- What is the Lab UHT sterilizer?

Laboratory ultra-high temperature sterilizers are specially designed to simulate industrial-scale processes, minimizing product requirements while ensuring continuous processing. The lab UHT sterilization machine covers an area of only 2 square meters and is controlled by Siemens PLC from Germany, making it easy to operate. The laboratory UHT sterilizer operates with only electricity and water to operate and has a inbuilt steam generator.

- How are Lab UHT sterilizers different from regular UHT sterilizers?

Lab UHT Sterilizer has the rated flow rate with 20L/H and 100L/H for your choice. And 3 to 5 Liters of product can complete an experiment. Lab scale UHT has a maximum sterilization temperature is 150℃. Lab UHT Processing Line completely simulates an industrial ultra-high temperature sterilization machine, and its process is the same. Experimental data can be directly used in production without pilot testing. The machine's temperature curve data can be copied to a USB flash drive to facilitate your paper writing.

Pilot UHT Plant accurately simulates preparation, homogenization, aging, pasteurization, UHT rapid sterilization, and aseptic filling. The machine workstation system integrates online CIP functions and can be equipped with the GEA homogenizer and aseptic filling cabinet according to your needs.

- The Significance of The Existence of Lab UHT Sterilization Processing Line:

Lab UHT Processing Line has important implications for laboratory-scale food production.

As consumers' requirements for food quality and safety continue to increase, the significance of Lab UHT Sterilizer in the food industry has become increasingly prominent. Lab scale UHT not only ensures the safety of microorganisms but also retains the nutritional ingredients and taste of food, meeting the needs of modern consumers for health and flavor.

It provides food scientists, researchers, and manufacturers with a platform to develop new products, test processes and evaluate food quality and safety under a variety of conditions.

1. Independent Germany Siemens or Japan Omron control system, using human-machine interface operation, simple operation and easy to use.

2. Lab UHT Processing Plant Completely simulates laboratory industrial production sterilization.

3. Equip with CIP and SIP online functions.

4. Homogenizer and aseptic filling cabinet can be configured as optional. Depending on the experimental requirements choose online homogenizer with upstream or downstream of the Lab UHT Processing Plant.

5. All data can be printed, recorded, and downloaded. Computer interface with real time temperature recording, the trial data can be used for the paper directly with excel file.

6. High accuracy and good reproducibility, and the test results can be scaled up to industrial production.

7. New product development saves materials, energy and time. The rated capacity is 20 liters/hour and the minimum batch size is only 3 liters.

8. Requires only electricity and water, the Lab scale UHT is integrated with a steam generator and refrigerator.

Shanghai EasyReal Machinery Co., Ltd was established in 2011, and specializes in manufacturing Lab equipment and Pilot Plant for fluid food and beverage and bioengineering, like Lab scale UHT, Lab UHT processing systems, and other liquid food engineering and whole line production lines. We are committed to providing users with a full range of services from R&D to production. We have obtained CE certification, ISO9001 quality certification, SGS certification, and have 40+ independent intellectual property rights.

Relying on the technical research and new product development capabilities of the Shanghai Academy of Agricultural Sciences and Shanghai Jiao Tong University, we provide lab and pilot equipment and technical services for beverage research and development. Reached strategic cooperation with German Stephan, Dutch OMVE, German RONO, and other companies. Keep pace with the times according to market conditions, continuously improve our own R&D & production capabilities, improve the production of each process, and strive to provide customers with the best production line solutions. Shanghai EasyReal will always be your wise choice.

Laboratory UHT sterilizers can be used to process a variety of liquid foods, such as milk, juice, dairy products, soups, tea, coffe and drinks, etc., opening up broader possibilities for food innovation.

Moreover, Lab UHT Processing Plant is versatile and can be employed for stability testing of food additives, color screening, taste selection, formula update and test of shelf life as well as in the research and development of new products.

1. Fruit and vegetable paste and puree

2. Diary and milk

3. Beverage

4. Fruit Juice

5. Condiments and additives

6. Tea drinks

7. Beer, etc.