Shanghai EasyReal, a leading provider of advanced processing solutions for the food and beverage industry, has announced the successful commissioning, installation, and training of a Lab Ultra-High-Temperature (UHT) processing line for Vietnam TUFOCO, a prominent player in Vietnam’s coconut product sector. This plant, mainly focused on coconut water and coconut milk production, marks a significant milestone in enhancing TUFOCO’s Beverage R&D and small-scale production capabilities.

________________________________________

Project Overview

The newly installed pilot UHT line is designed to meet TUFOCO’s requirements for processing coconut-based beverages, which demand precise temperature control, aseptic handling, and nutrient retention to preserve natural flavors. The compact, modular system features EasyReal’s proprietary Lab Scale UHT System, capable of processing 20 liters per hour while ensuring product stability and extended shelf life.

EasyReal’s solution integrates advanced heat exchange systems, direct steam injection (DSI) technology, and automated controls to optimize processing parameters, ensuring minimal nutrient loss and consistent product quality. It provides great support for the company’s Beverage Development and Functional Beverage innovation.

________________________________________

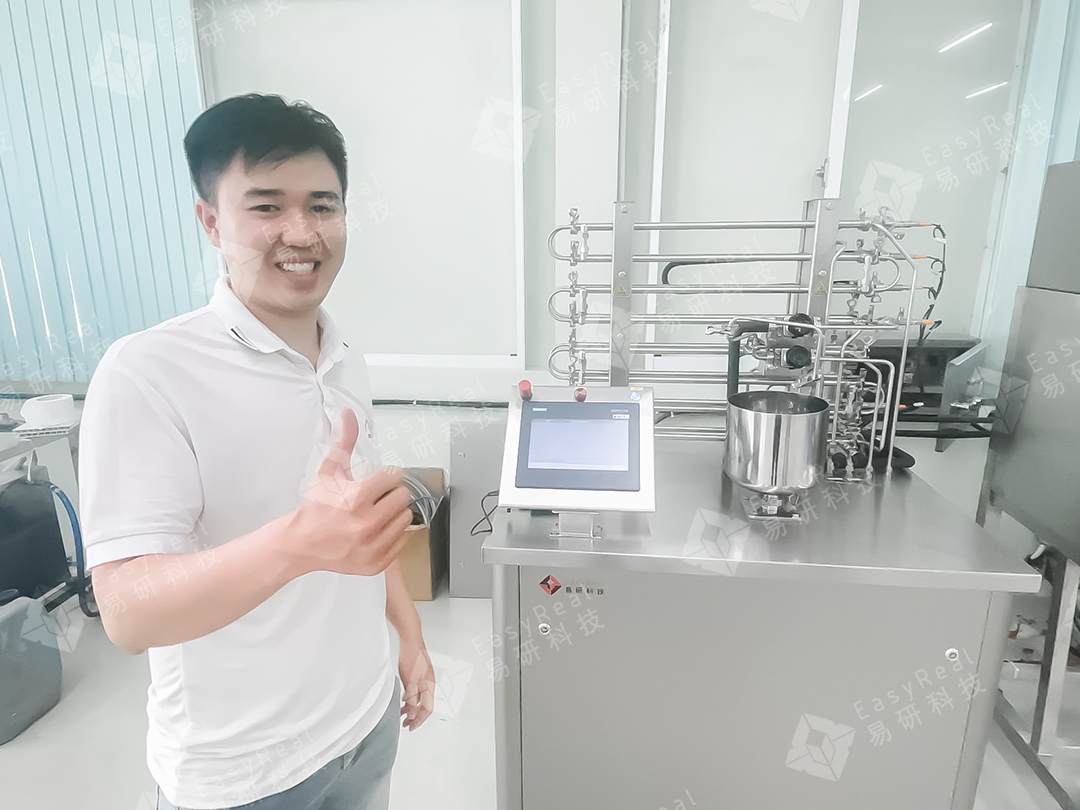

Seamless Execution and Client Satisfaction

The Shanghai EasyReal team completed the installation and commissioning within the agreed timeline, followed by comprehensive training for TUFOCO’s technical staff. The training covered equipment operation, maintenance protocols, troubleshooting, and aseptic filling system (Aseptic Filling Equipment for Juices) operation, empowering TUFOCO to independently manage the pilot line for future product development.

The TUFOCO team praised the collaboration, highlighting EasyReal’s engineering expertise in pilot-scale aseptic filling machine and its commitment to Food Safety and Quality Control.

________________________________________

Precision Engineering for Product Challenges

The pilot UHT line integrates EasyReal’s indirect heating UHT technology, specifically optimized for heat-sensitive, high-sugar coconut products. Key innovations include:

• Double-layer Tube Heat Exchanger: Ensures uniform thermal distribution, preventing protein denaturation and caramelization, critical for preserving natural flavor and color.

• Instant Cooling Modules: Rapidly reduces product temperature post-UHT treatment (140–145°C for 3~5 seconds) to below 40°C within seconds, minimizing thermal degradation.

• Aseptic Filling Integration: Combines UHT processing with Class 100 cleanroom-grade aseptic filling, ensuring sterile product stability.

• Parameter Optimization: Real-time adjustment of temperature, pressure, and flow rates, ensuring consistency across varying raw material viscosities.

________________________________________

Looking Ahead

The success of this project reinforces EasyReal’s reputation as a trusted partner for Southeast Asia’s thriving food and beverage sector. Both companies have expressed interest in exploring further collaborations, including potential expansions to full-scale production lines and alternative protein beverage processing.

For more information about Shanghai EasyReal’s solutions, visit www.easireal.com or contact sales@easyreal.cn.

For Inquiries:

WhatsApp: +86 15734117608

Email: sara_cao@easyreal.cn

Website: www.easireal.com

Post time: Mar-07-2025