March 3, 2025 — Shanghai EasyReal Intelligent Equipment Co., Ltd., a global leader in compact food and beverage processing solutions, proudly announces the successful installation, commissioning, and acceptance of its Laboratory UHT/HTST Pilot Plant for FGC, a pioneering Vietnamese company in tea and functional beverage production. This milestone underscores EasyReal’s commitment to delivering cost-effective, small-scale UHT solutions tailored for R&D and pilot-scale production.

Project Overview

Renowned for its premium tea exports, FGC is expanding into the functional beverage sector. To accelerate product innovation, the company has selected EasyReal’s 20LPH Lab UHT/HTST Plant (learn more), a modular system designed for research and development across various liquid food applications, including tea, functional beverages, coffee, dairy, milk, and plant-based beverages.

Key Components:

- Pilot Tubular UHT/HTST Sterilizer – Achieves precise sterilization (up to 152°C, ±0.3°C) for diverse liquid food products.

- Inline Homogenizer – Enhances emulsion stability and protein solubility, ensuring uniform texture and improved product quality.

- Aseptic Filling System – Provides contamination-free aseptic packaging trials, simulating industrial production conditions.

- Direct Steam Injection (DSI) System – Enables rapid heating and precise control, ideal for sensitive beverages.

- Supporting Equipment – Includes an industrial ice water generator and an oil-free air compressor for enhanced operational efficiency.

Technical Excellence & Client Benefits

EasyReal’s lab-scale pasteurizer and UHT pilot plant integrate advanced features that optimize R&D efficiency:

- Modular Flexibility – Easily adapt workflows for milk, ice cream, plant-based beverages, tea, coffee, RTD (ready-to-drink) drinks, and dairy products.

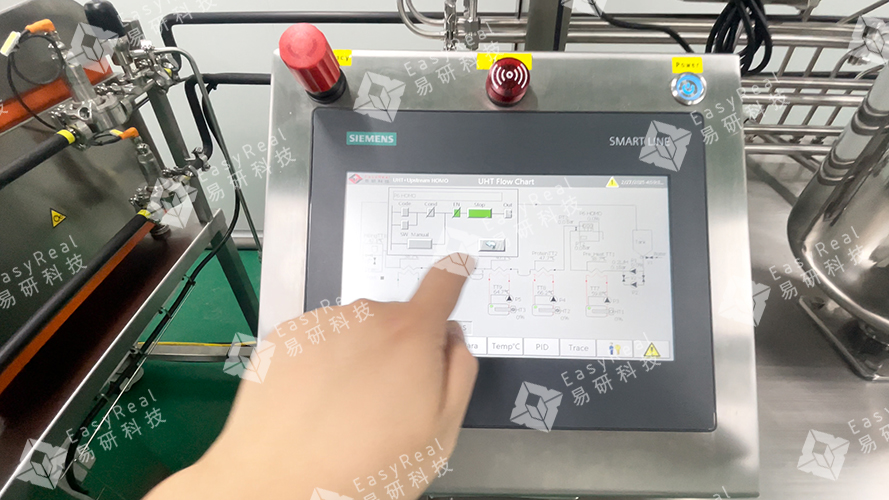

- Precision Control – Real-time temperature, flow rate (5–40 L/h), and pressure monitoring via an intuitive touchscreen interface. (EasyReal also offers a 100L/h model for larger-scale testing.)

- Low Operational Costs – Requires only 3 liters per test, reducing raw material waste by 40% compared to traditional systems.

- Extended Shelf Life – Optimized UHT processing with minimal heat damage ensures nutrient retention and prolonged freshness.

- Simulated Industrial Production – Bridges the gap between laboratory testing and full-scale manufacturing, facilitating smooth scale-up.

Strategic Impact

For Future Generation PHU THO, this UHT mini system serves as a crucial link between laboratory research and industrial-scale production, delivering:

- Faster Time-to-Market – Shortens prototype development cycles by 50–60%, enabling rapid response to evolving market demands.

- Quality Assurance – Fully CE-compliant, ensuring export-ready product quality.

- Scalability – Seamlessly transitions from pilot-scale testing to commercial production, minimizing capital investment risks.

- Reduces Food Waste – Optimized processing ensures efficient use of raw materials, reducing overall waste.

FGC’s R&D Director stated:

“EasyReal’s small-scale UHT system empowers us to innovate with confidence. Its precision and flexibility align perfectly with our commitment to premium-quality beverages.”

Why Choose EasyReal’s UHT Pilot Plant?

- Proven Expertise – Trusted by leading global brands, with consistently positive customer feedback.

- Customizable Solutions – Designed to meet specific processing needs for milk, dairy, coffee, tea-dairy blends, plant extractions, nut milks, and probiotic beverages.

- End-to-End Support – Comprehensive installation, commissioning, training, and regulatory compliance assistance.

- Scalable and Cost-Effective – Supports seamless scale-up from pilot to industrial production, offering high cost-performance.

About Shanghai EasyReal

As a National High-Tech Enterprise based in Shanghai, China, EasyReal specializes in laboratory-scale pasteurizers and UHT pilot plants. Supporting innovators in 30+ countries, its 20LPH and 100LPH modular systems are recognized for their precision, scalability, and compliance.

Explore our solutions: www.easireal.com/20lph-lab-uhthtst-plant

For Inquiries:

Whatsapp:+86 15711642028

Email:jet_ma@easyreal.cn

Website:www.easireal.com

Contact: Jet Ma, Global Marketing Director | jet_ma@easyreal.cn

Innovate Faster, Scale Smarter.

Post time: Mar-04-2025