The Future of Liquid Sterilization Without Additives

In the rapidly evolving food and beverage industry, consumers are becoming increasingly conscious about the products they consume, particularly regarding the ingredients used. Among the most significant trends is the growing demand for food and beverages that are free from artificial additives, preservatives, and other synthetic ingredients. This shift has led to substantial advancements in liquid sterilization and shelf-life extension technologies, specifically in achieving longer-lasting products without the need for additives. But how far have we really come in this area?

Understanding the Challenge: Natural Preservation Without Additives

The challenge of preserving liquid-based food products without relying on artificial preservatives is not new. For years, the food industry has struggled with finding methods that extend shelf life while maintaining product quality, safety, and nutritional integrity. Conventional preservation methods, such as the use of chemical additives or pasteurization, often alter the taste, texture, or nutritional profile of the product, which is not ideal for today’s more health-conscious consumer.

Liquid sterilization, which involves the process of eliminating harmful microorganisms from liquids to increase shelf life, is one of the key technologies that has undergone significant innovation in recent years. However, the breakthrough here is not just improving the sterilization process but doing so without compromising the natural qualities of the product, especially for popular products like tomato sauce, mango puree, and coconut water.

The Rise of Modern Liquid Sterilization Technologies

Modern liquid sterilization methods, particularly Ultra-High Temperature (UHT) processing and direct steam injection, have made it possible to sterilize products at extremely high temperatures for very short periods of time. This rapid heating and cooling process allows for the destruction of bacteria and other pathogens, significantly extending shelf life without the need for added preservatives. These methods are becoming particularly important in industries where preserving the natural flavor and nutrients of products like tomato sauce, mango puree, and coconut water is a top priority.

UHT, for example, is widely used in dairy and fruit juice production, but its application to products like tomato sauce production lines and mango puree production lines has also proven to be effective. The key advantage of this technology is its ability to preserve the flavor and nutrients of the product while ensuring microbial safety. As UHT technology has advanced, it has become more energy-efficient and effective in maintaining the natural characteristics of the liquid, whether it’s the sweetness of mango puree or the refreshing quality of coconut water.

Another innovation in liquid sterilization is direct steam injection sterilization. This method uses steam to heat the liquid quickly, ensuring sterilization while minimizing the time the liquid is exposed to high temperatures. This helps retain the taste and nutritional value of the product, and is particularly beneficial for coconut water production lines, where maintaining the freshness and natural properties of the liquid is crucial for consumer appeal.

The Importance of Lab UHT Machines and Pilot Plants

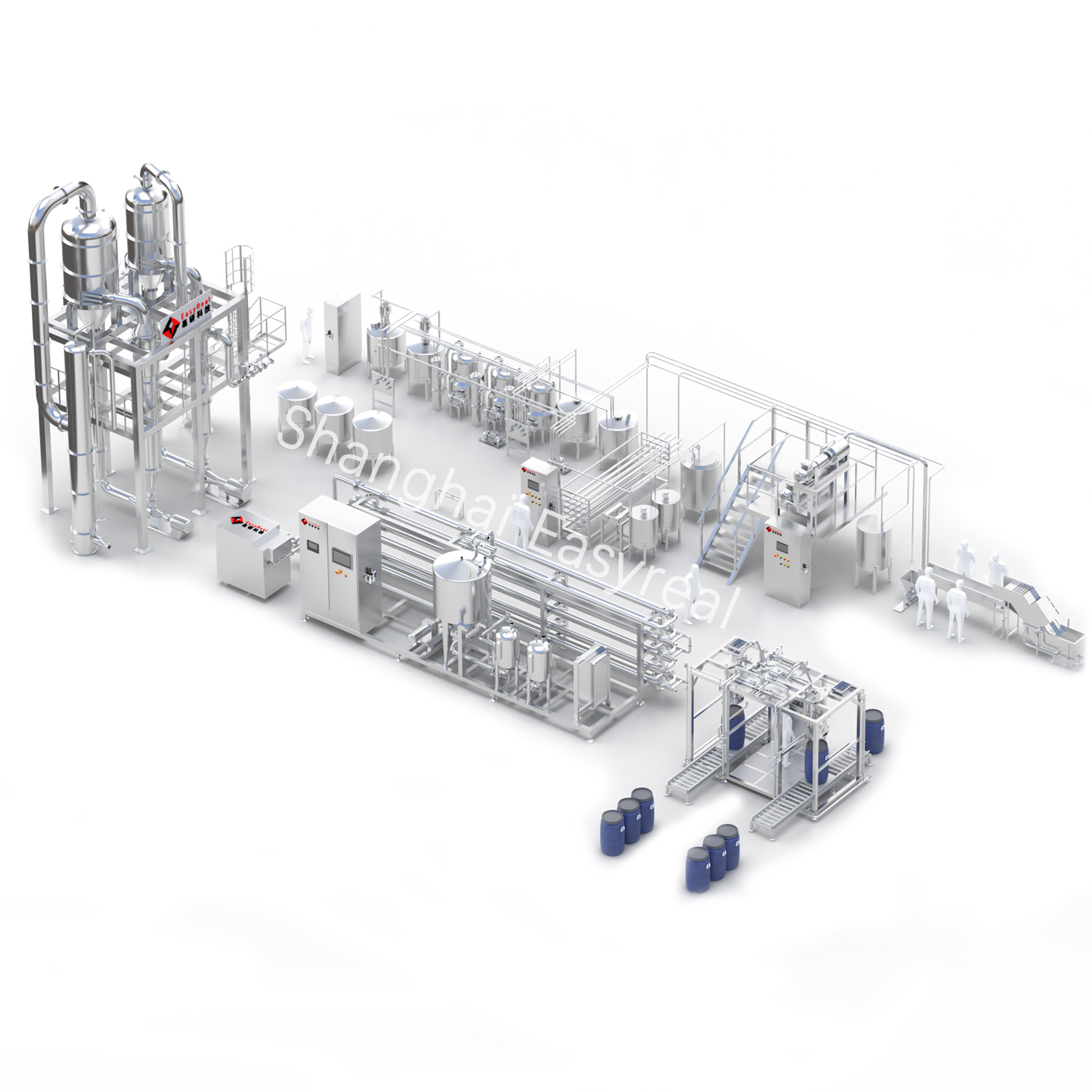

While liquid sterilization technologies like UHT and direct steam injection have made substantial advancements, manufacturers need to ensure these technologies are fully optimized before scaling to larger production lines. This is where lab UHT machines and pilot plants play a critical role, especially in the context of specific production lines like those for tomato sauce, mango puree, and coconut water.

- Lab UHT Machines: These machines allow manufacturers to test UHT processes on a smaller scale, closely replicating the conditions of large-scale production. For example, testing different UHT parameters on tomato sauce or mango puree allows manufacturers to fine-tune the process to ensure that these products maintain their rich flavors and textures while achieving the necessary shelf life. The same applies to coconut water, where temperature and time control are vital to preserving the fresh, natural qualities of the beverage.

- Pilot Plants: Pilot plants serve as a bridge between laboratory-scale tests and full-scale production. They provide a realistic setting for testing new sterilization methods, formulations, and production processes on a small but larger scale than lab settings. For example, pilot plants allow manufacturers to test the scalability of new sterilization methods on a tomato sauce production line or mango puree production line. This helps refine the processes and ensure that when the technology is scaled up, it will maintain the same quality and efficiency, whether for small batches or mass production.

Without lab UHT machines and pilot plants, the risk of investing in unproven technologies and processes increases significantly. These facilities provide the essential data needed to make informed decisions about scaling up production, reducing the potential for costly mistakes and ensuring that the final product meets both safety standards and consumer expectations.

The Progress: Where Are We Now?

The real question is: how much progress has been made in liquid sterilization and shelf life extension without additives? The answer is that the food and beverage industry has made substantial headway, but there are still challenges to overcome.

- Improved Sterilization Techniques: Advances in UHT and direct steam injection technology have made it possible to extend the shelf life of liquids without altering their original taste or nutritional content. These technologies have been continuously refined to offer better energy efficiency, faster processing times, and a more precise control over temperature, all of which contribute to a superior product.

- Consumer Preferences Shaping Innovation: Today’s consumers are more aware than ever of what goes into their food and beverages. This shift in consumer preference has led to an increased focus on natural preservation methods that avoid the use of artificial chemicals. This demand has driven the development of newer, more effective sterilization processes.

- Scaling for Mass Production: While many of these advancements have been successful on a smaller scale, the ability to scale these processes for mass production without losing efficiency or product quality is still an ongoing area of development. However, the industry is making strides in adapting these advanced technologies for use in larger facilities while maintaining the same level of product integrity, whether for tomato sauce, mango puree, or coconut water production lines.

- Maintaining Nutritional Integrity: Perhaps the most important milestone in recent years is the ability to preserve the nutritional value of liquid foods. The latest sterilization techniques have been designed with the goal of ensuring that the vitamins, minerals, and antioxidants in products like fruit juices, tomato sauces, and coconut water remain intact, despite the sterilization process.

The Future of Liquid Sterilization Without Additives

Looking ahead, it is clear that the future of liquid sterilization is leaning towards even more sophisticated and efficient systems. As research continues, we can expect to see improvements in process control, energy efficiency, and the ability to preserve not just the safety of the product but its original qualities. There may also be a rise in alternative, non-thermal preservation methods, such as high-pressure processing (HPP), which could complement or even replace traditional heat-based sterilization in certain applications.

For Manufacturers, the Challenge Lies in Balancing Cutting-Edge Technologies

For manufacturers, the challenge will lie in balancing these cutting-edge technologies with consumer expectations for affordability, accessibility, and sustainability. As consumer demand for additive-free products continues to grow, those who can leverage these advancements in liquid sterilization will be at the forefront of a new era of food and beverage production—one that focuses on quality, safety, and natural preservation.

Conclusion

In conclusion, significant progress has been made in liquid sterilization and shelf-life extension technology without the need for additives. Technologies like UHT processing and direct steam injection have made it possible to preserve liquids effectively while maintaining their natural flavors and nutrients. The role of lab UHT machines and pilot plants in testing, refining, and scaling these technologies is essential for ensuring that new sterilization methods can be safely and efficiently integrated into large-scale production. Whether it’s the production of tomato sauce, mango puree, or coconut water, these advancements in liquid sterilization are helping manufacturers meet the growing consumer demand for high-quality, additive-free products. As these technologies continue to evolve, we are on the cusp of a new era in food and beverage production that focuses on quality, safety, and natural preservation.

Post time: Feb-12-2025